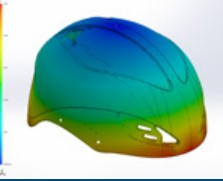

SOLIDWORKS® Plastics delivers easy-to-use simulation for analyzing plastic parts and injection molds. It simulates how melted plastic flows during the injection molding process to predict manufacturing-related defects so you can quickly evaluate part manufacturability while you design.

Learn More About SOLIDWORKS Plastics

SOLIDWORKS Plastics Datasheet

SOLIDWORKS® Plastics helps you predict and avoid manufacturing defects during the earliest stages of part and mold design, eliminating costly mold rework, improving part quality, and decreasing time-to-market.

Reject Risk in Mold Injection with SOLIDWORKS Plastics

SOLIDWORKS® Plastics takes the guesswork—and the risk—out of designing plastic parts, allowing you to accurately assess manufacturability, functionality, and quality, throughout the design process.

Know Your Designs Will Pass the Injection-molding Process

Producing high-quality, plastic injection-molded parts more quickly and cost-effectively than the competition has become a critical factor for manufacturing success in today’s global market.