Markforged X3

X3™

The refined Industrial FFF 3D printer for micro carbon fiber filled nylon parts.

The X3 merges industrial quality and build volume into a benchtop form factor, bringing FFF composite 3D printing to your manufacturing floor.

Manufacturing-Grade FFF Printing

|

Wide Variety of Optimized Print Modes |

Industrial Reliability and Accuracy

|

|

The X3 brings three versatile, advanced, micro carbon fiber filled nylon materials to a precision-built Fused Filament Fabrication (FFF) 3D printing platform, delivering functional part after functional part. |

Print in a wide variety of print modes all optimized to yield quality parts — including 50 μm resolution, which delivers ultra-high-quality parts without visible layer lines. |

Precision-machined hardware, advanced sensors, and unique software drive leading edge accuracy and reliability. Markforged industrial carbon fiber 3D printers offer micron-level laser scanning for closed-loop calibration, reliably yielding parts with high repeatability and near-perfect surface finish. |

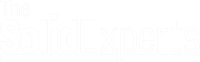

Simple FFF Process. Robust Parts.

| Physical Dimensions | Build Volume |

| Width: 584 mm | Width: 330 mm |

| Depth: 483 mm | Depth: 270 mm |

| Height: 914 mm | Height: 200 mm |

| Weight: 46 kg / 102 lbs |

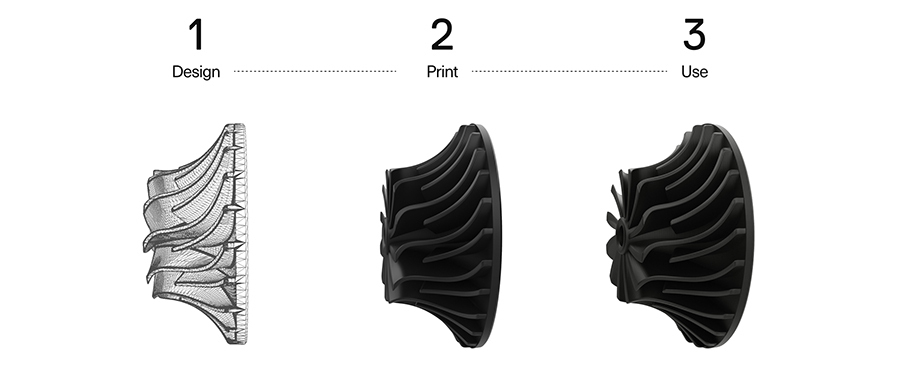

Printing Process: Fused Filament Fabrication (FFF)

Z Layer Resolution: 50 μm - 200 μm

Printing Media: Composite Base Filaments

Internal Part Geometry: Closed Cell Infill, Triangular Default

Print Bed: Precision Ground Composite

Print high-quality parts with Markforged's micro carbon fiber reinforced nylon filaments.

.png?width=524&height=790&name=X3%20(1).png)