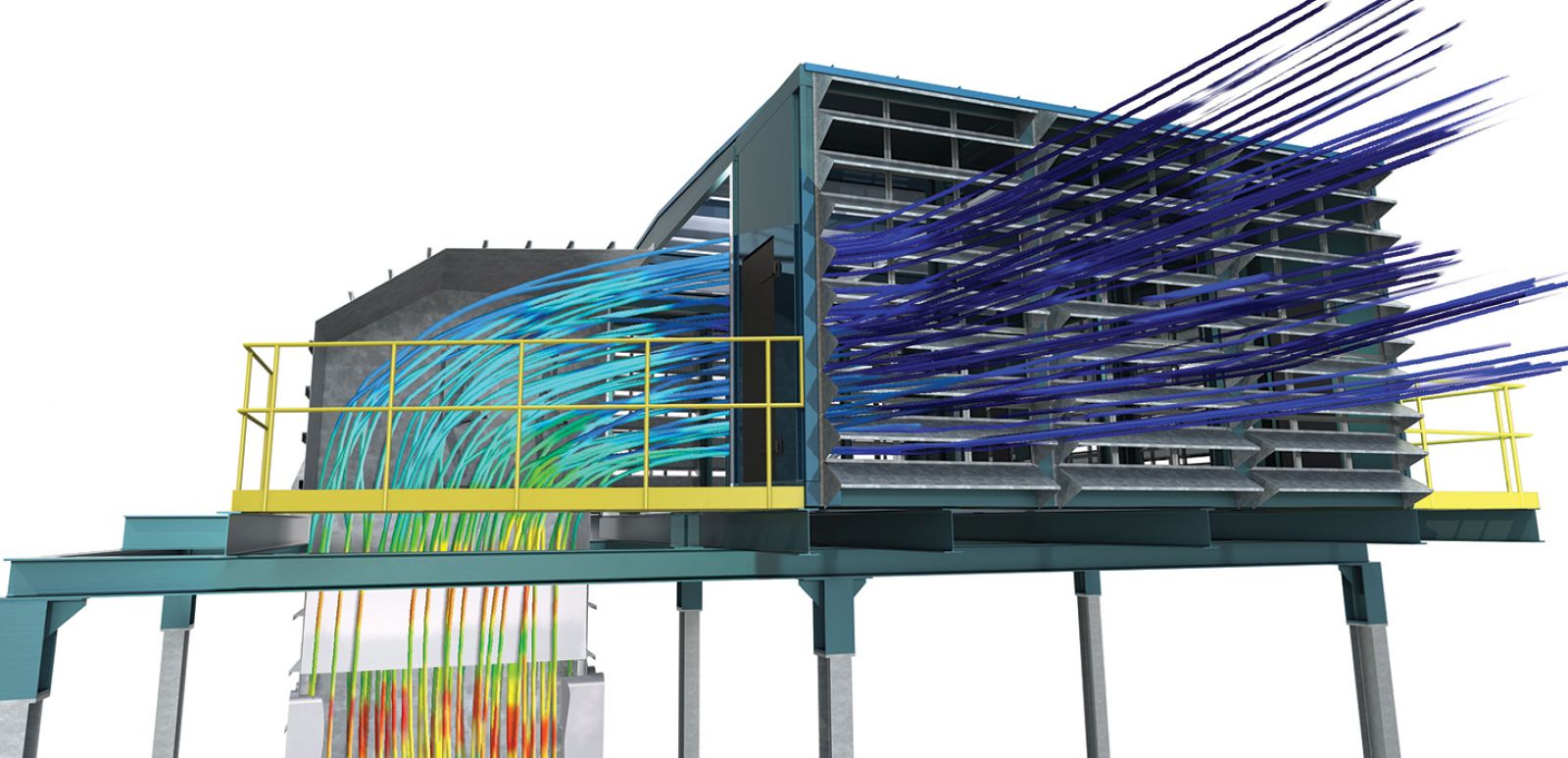

SOLIDWORKS® Flow Simulation is an intuitive Computational Fluid Dynamics (CFD) solution embedded within SOLIDWORKS 3D CAD that enables you to quickly and easily simulate liquid and gas flows through and around your designs to calculate product performance and capabilities.

Learn More About SOLIDWORKS Flow Simulation

Customer Story: Optar Technologies Ltd.

Optar Technologies needed to acquire tools for developing innovative, cost-effective solutions for the many design and engineering challenges associated with the development of air intake filter housing systems for a variety of applications.

Adding Advanced Plastics and CFD Virtual Testing Capabilities to Your Design Workflow

Solve your most advanced CFD and plastic engineering challenges by adding advanced virtual testing capabilities to your design workflow

Intuitive CFD Analysis at Your Fingertips

With integrated CFD tools you can efficiently analyze the effects of fluid flow, heat transfer, and related forces on your projects and process multiple “what if” scenarios to help you optimize designs quickly.