SOLIDWORKS 3D CAD solutions provide easy-to-learn, yet extremely powerful functionality that shortens product development time, reduces costs, and improved quality.

Dramatically improve the way you develop and manufacture products. As the foundation for the entire SOLIDWORKS suite of product development solutions, SOLIDWORKS CAD packages cover design, simulation, cost estimation, manufacturability checks, CAM, sustainable design, and data management.

Discover the power of SOLIDWORKS, the industry-leading 3D CAD software that revolutionizes the way you design and develop your products. Whether you're a seasoned engineer or just starting your journey in product design, SOLIDWORKS provides you with the tools and capabilities to bring your ideas to life.

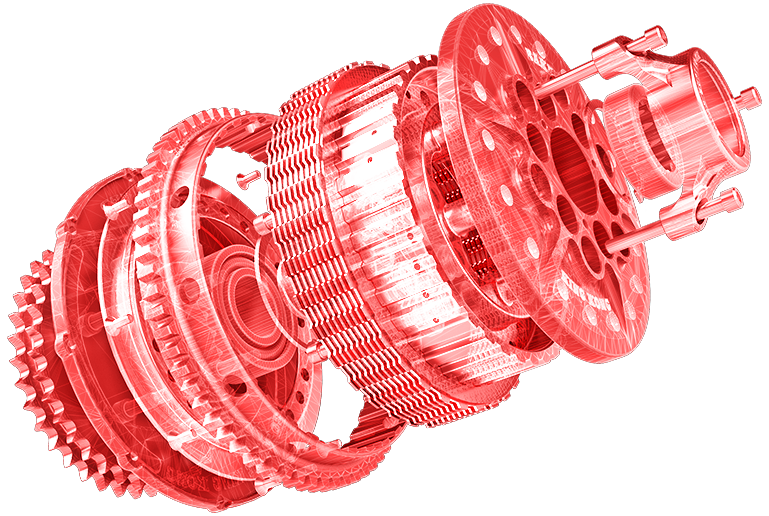

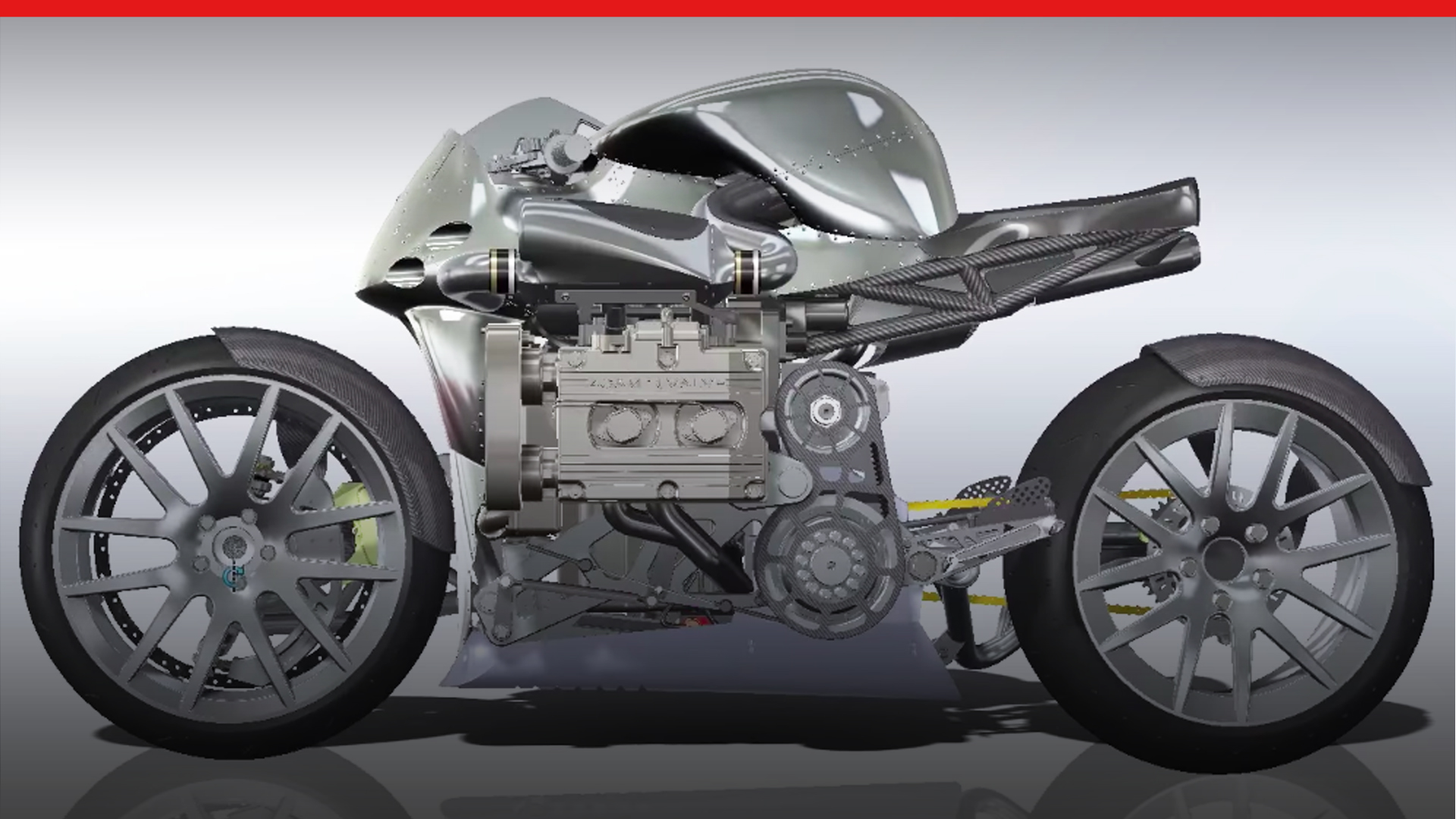

With SOLIDWORKS 3D CAD, you can create precise 3D models of your designs, enabling you to visualize and validate your concepts before production. The intuitive user interface and robust modeling features empower you to design complex assemblies, parts, and surfaces with ease

SOLIDWORKS Standard

Get up to speed quickly and benefit from this powerful 3D design and manufacturing solution. Along with part, assembly, and 2D drawing functionality, specialized tools are included for sheet metal, weldments, surfacing, molds, product configuration, design analysis, DFM, and CAM. CAM included with an active subscription.

SOLIDWORKS Professional

SOLIDWORKS Professional builds on the capabilities of SOLIDWORKS Standard to increase design productivity, with file management tools, advanced photorealistic rendering, automated cost estimation, eDrawings® Professional collaboration capabilities, automated design and drawing checking, and a sophisticated components and parts library.

SOLIDWORKS 3D CAD Datasheet

As the foundation of the entire SOLIDWORKS® suite, SOLIDWORKS 3D CAD solutions provide easy-to-learn, powerful functionality that helps you shorten product development time, reduce costs, and improve quality.

First Look: SOLIDWORKS CAD

SOLIDWORKS® CAD provides dedicated tools and workflows that streamline the design and development of your products from concepts through to reality.

SOLIDWORKS 3D CAD Top Enhancements

Check out the top 10 enhancements in SOLIDWORKS® 2023 - 3D CAD. From enhanced assembly workflows to improved part modeling, sheet metal capabilities, and more.